About

Shiva PolyPack

Shiva PolyPack is a leading pouch manufacturing company in Punjab, India, offering premium, customizable packaging solutions for diverse industries. Our pouches are durable, food-safe, and high-barrier, designed to protect freshness and enhance brand appeal.

Our Products: Stand-up & zipper pouches, Printed & laminated pouches, Food-grade & industrial packaging.

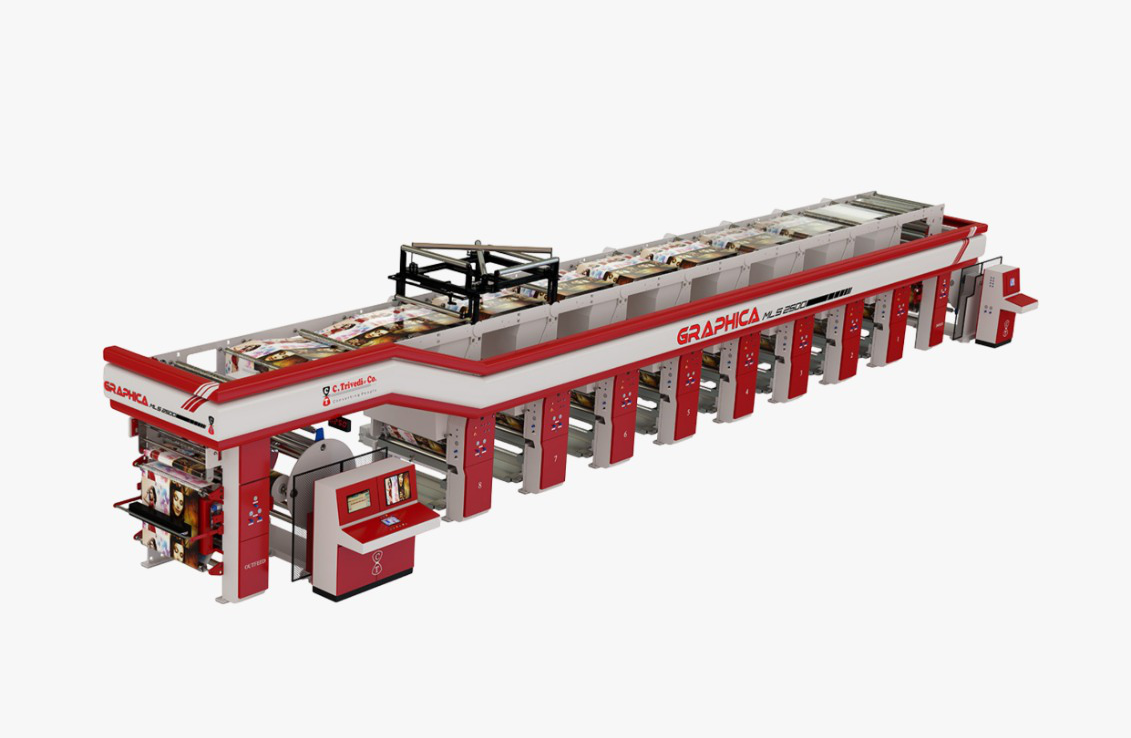

High-Tech Printing Machine

Our advanced printing machines are designed for precision and clarity.

Whether it’s vibrant logos, detailed product information, or compliance barcodes,

we ensure every pouch looks premium.

Using rotogravure and digital printing technologies, we deliver

high-resolution graphics that enhance shelf appeal and brand recognition.

Precision Cutting Machine

After printing, our automated cutting machines shape each pouch

with unmatched accuracy.

From stand-up pouches to zip-lock bags, the machine ensures

clean edges and consistent sizes,

improving durability and functionality.

This guarantees every pouch is ready to withstand

storage, transport, and retail handling.

Building Trust & Quality in Packaging

Since our inception in 2024, we have been dedicated to delivering innovative packaging solutions that combine durability, functionality, and visual appeal. Our journey is built on commitment to quality, cutting-edge technology, and customer satisfaction.

Guided by

Mr. Sahil

Founder & Director

FAQ

95% of all orders are handed over to our shipping & logistics partners the very next working day (within 24 hrs). Custom printed orders take an additional 3 days for artwork approval and CTP/plate making. Majority of our orders are delivered within 2 days after shipment via Blue Dart, Delhivery, India Post, etc. Remote locations and ones affected by lockdown may take longer.

Please e-mail your request to sales@upack.in and we will be happy to provide a bulk quotation for packaging materials, customised boxes, carton boxes, packing tapes, bubble roll, stretch film, etc.

Although most of our sales are business to business, we can sell to any type of customer.